The DYNAFLO-C2 is a hydraulic headbox specially designed for Crescent Formers and for two-layers tissue grades, at speeds from 1,000 to 2,500 mpm, and basis weight from 10 to 40 gsm.

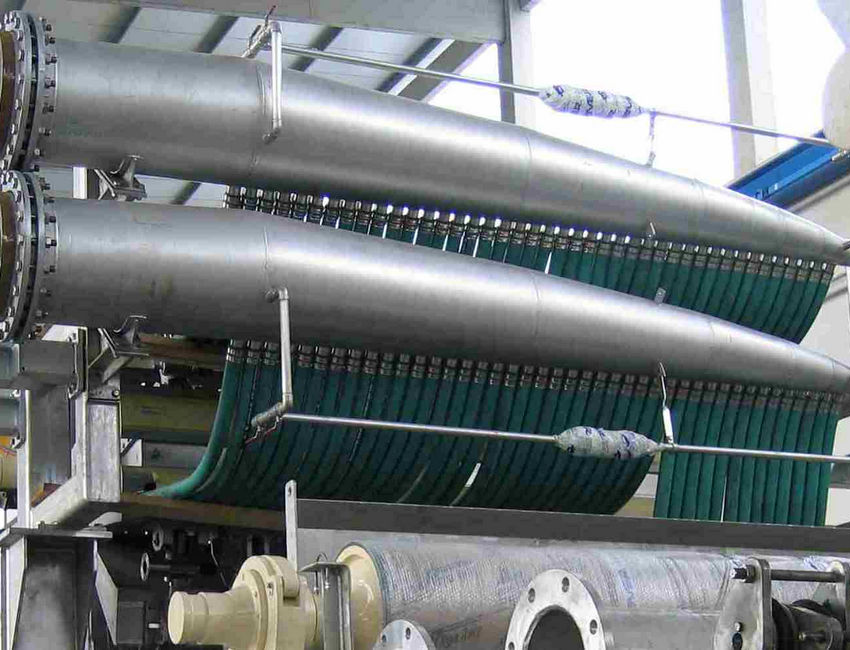

The excellent stock dispersion is guaranteed by the exclusive Dynaflo tubes, the turbulence generating device at the basis of the OVER's modern hydraulic headbox design. The flow coming from the tapered headers passes through a separated mixing/equalizing chamber that optimizes the stock pressure and fiber suspension, just before the turbulence generator of each layer, which is the core of the DYNAFLO concept. The stainless steel Dynaflo tubes present a conical cross-section, changing shape gradually from round to rectangular.

After a high acceleration at the inlet orifice and a gradual diffusion of the stock flow along the Dynaflo tubes, the large-scale turbulence weakens, while sustaining small-scale turbulence, thanks to the many boundary layers generated by the friction with the tube walls. Each tubes row has an optimum velocity range: by multiplying the tubes row, a great range of flow rates can be accommodated, this gives the headbox a great adaptability to all operating conditions. The configuration of the tubes rows ensures a negligible residual wake signature on the stock jet.

The headbox is supplied with stiff lamellas in the slice area, that maintain high the level of micro-turbulence up to the jet exit, improving paper formation at high speeds. The special lamellas' tip design avoids the wake effect in the slice flow. The beak-like nozzle allows a minimal free jet length, essential for good performances at the highest operating speeds. The design of this headbox allows a complete separation of the two layers, ensuring a purity higher than 90%.

Its entire construction in 316 L stainless steel, with thorough finish and electropolishing of all the surfaces in contact with the stock, will guarantee safe and trouble-free operations for many years. The CD profiling is made either manually or automatically, QCS driven, by micro-screw jacks spaced 150 mm, or optionally 100 mm. The dilution profiling of one of the two layers is also available through QCS control.

Our team is ready to assist you from the design phase to the complete turn-key service. Ask more information.